RHKINGS

RHKING® Rotary Broach Wobble Broach Tool Holder

RHKING® Rotary Broach Wobble Broach Tool Holder

Couldn't load pickup availability

● 30-Day Money Back Guarantee

● We ship via FedEx/DHL/UPS. Delivery usually takes around 3 weeks from the date of your order.

● $4.99 for worldwide shipping or free shipping over $100

Product Features

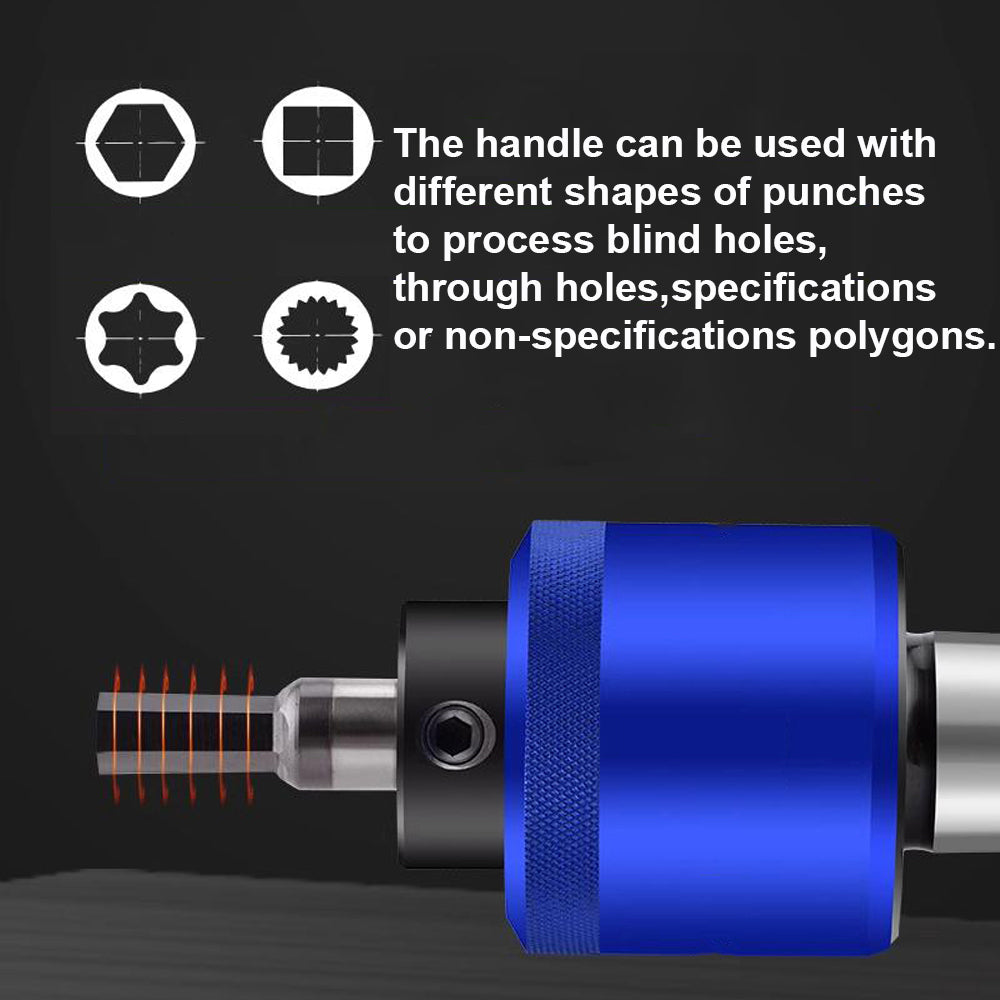

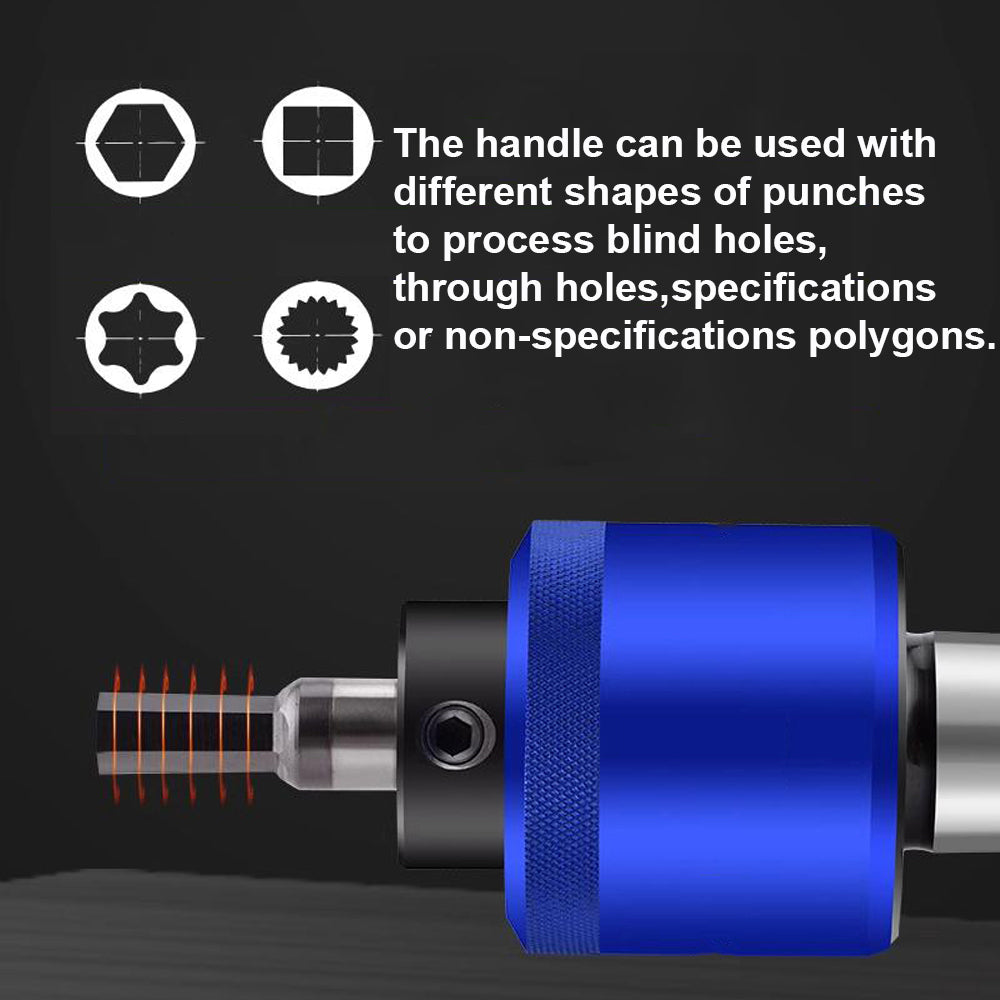

function: the rotary punching tool handle only needs to replace the rotary Broach, which can be rushed out of the hexagonal, internal square, internal spline and other special-shaped holes

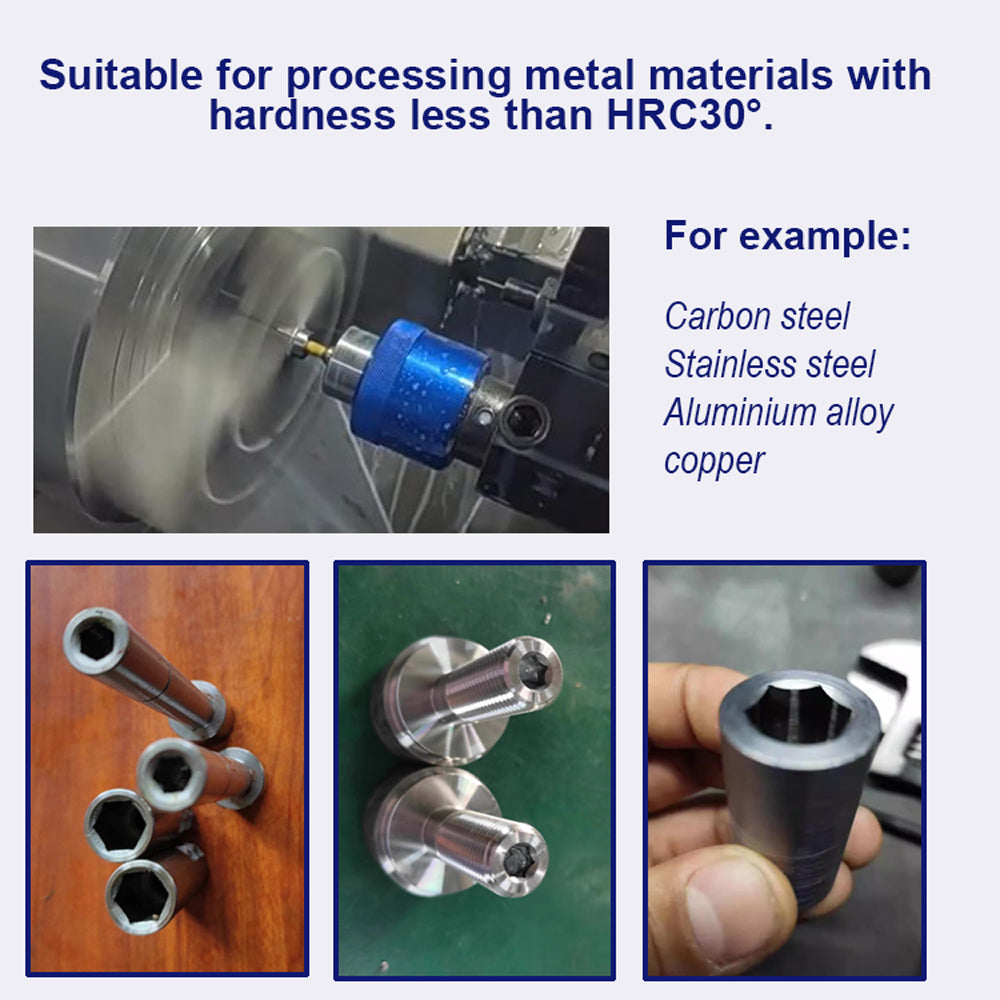

Processing:The Rotary Broach can process materials with hardness HRC30 or less, including carbon steel, stainless steel, copper and aluminum. Can processing blind hole .

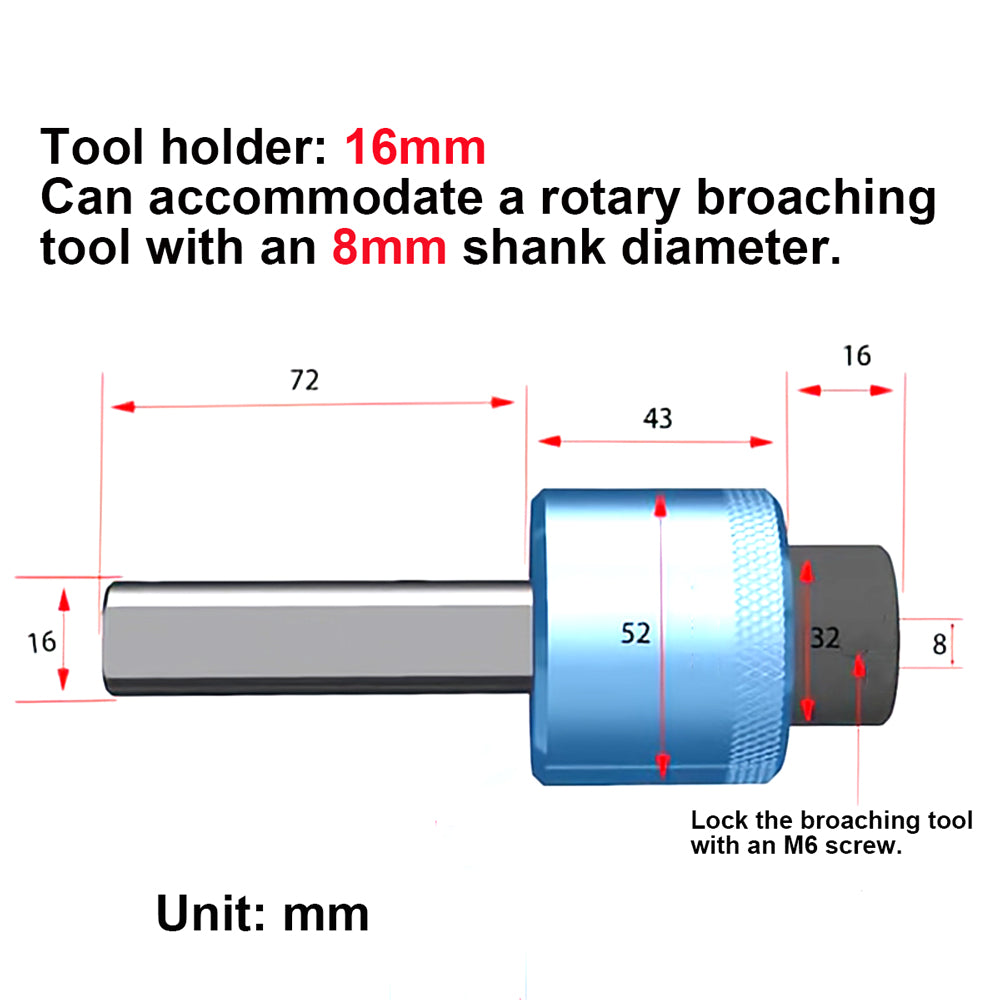

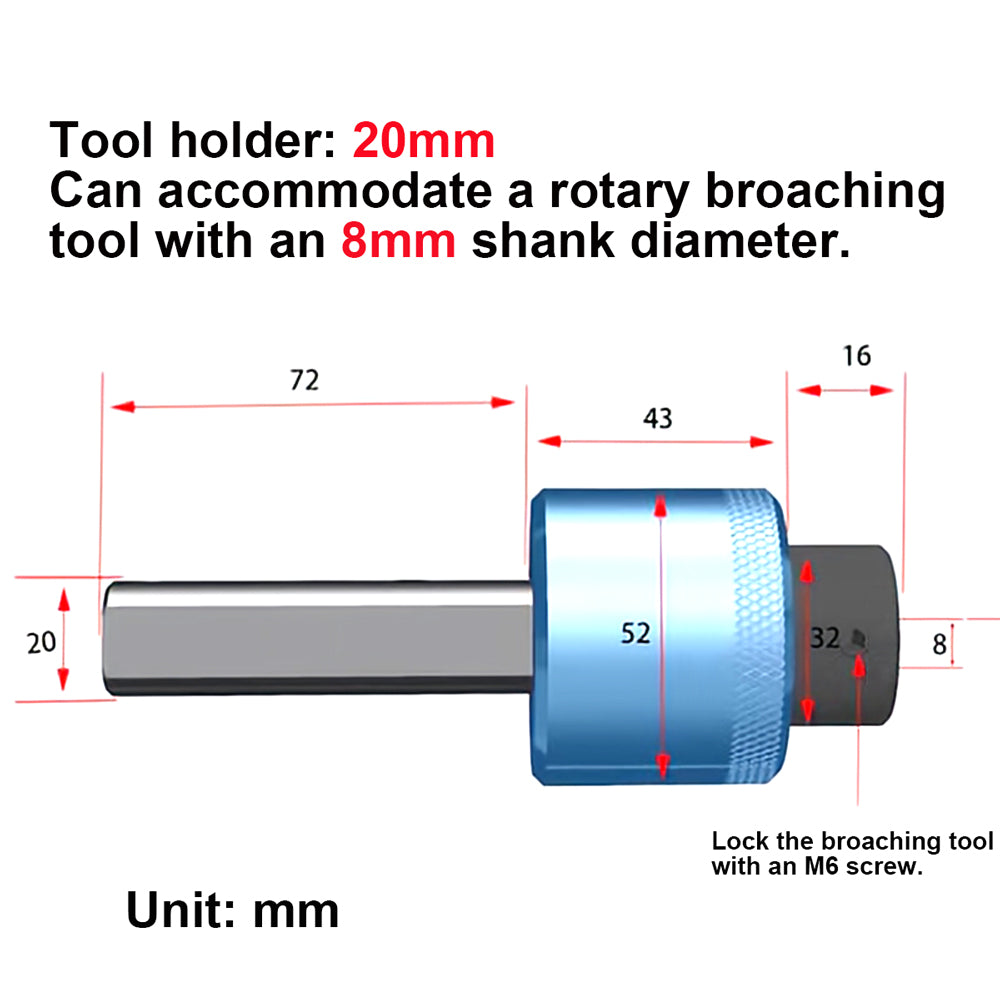

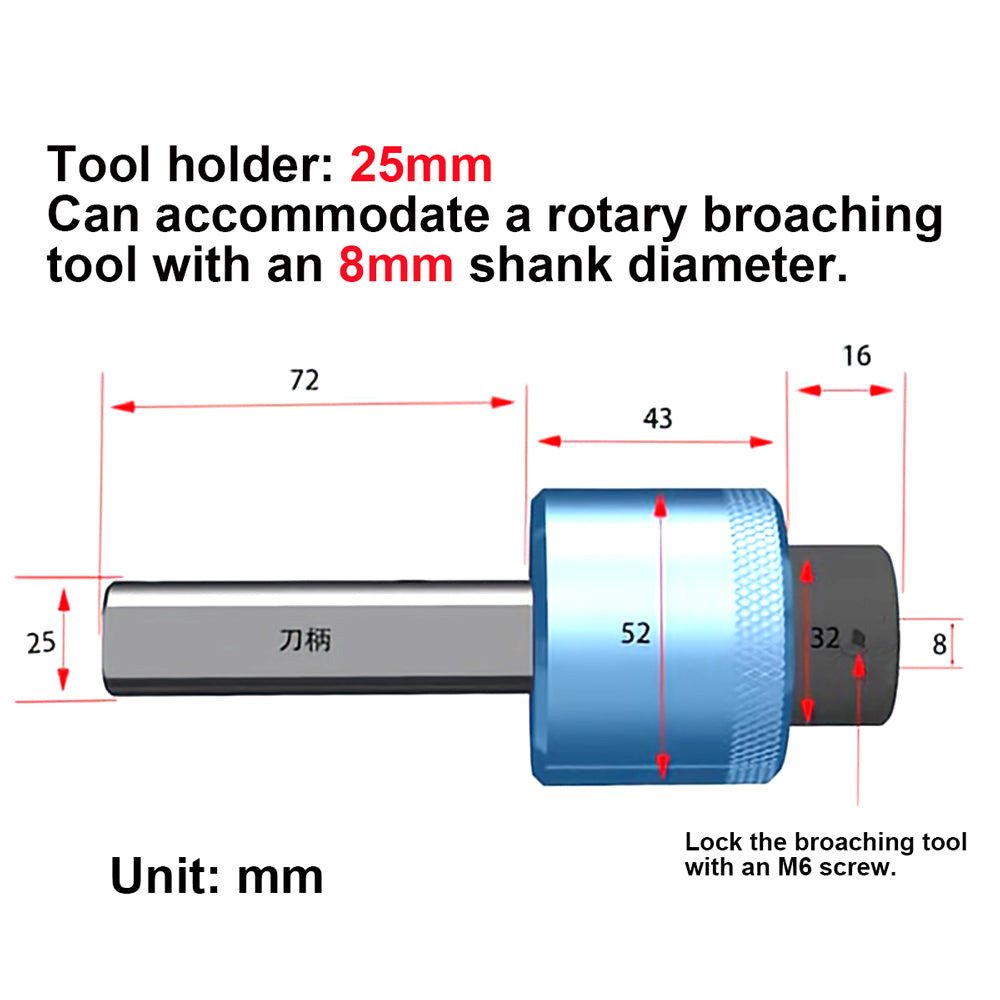

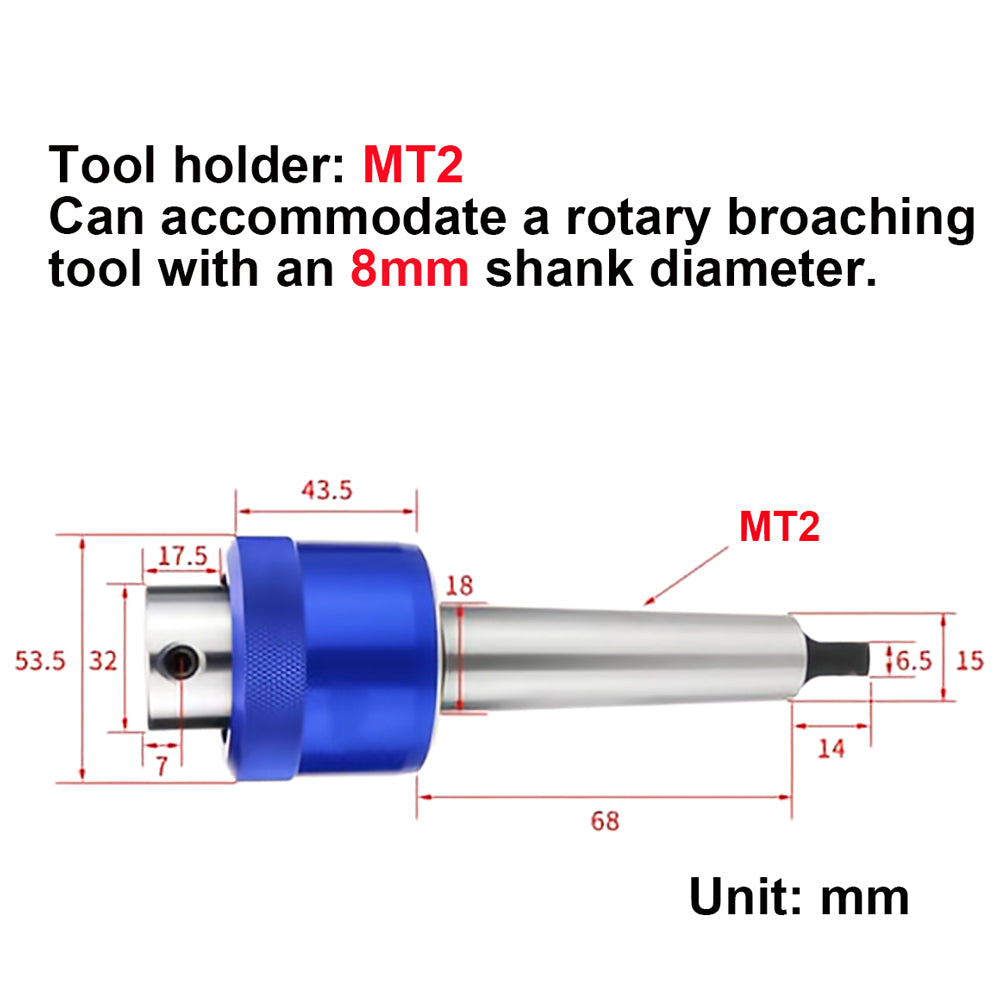

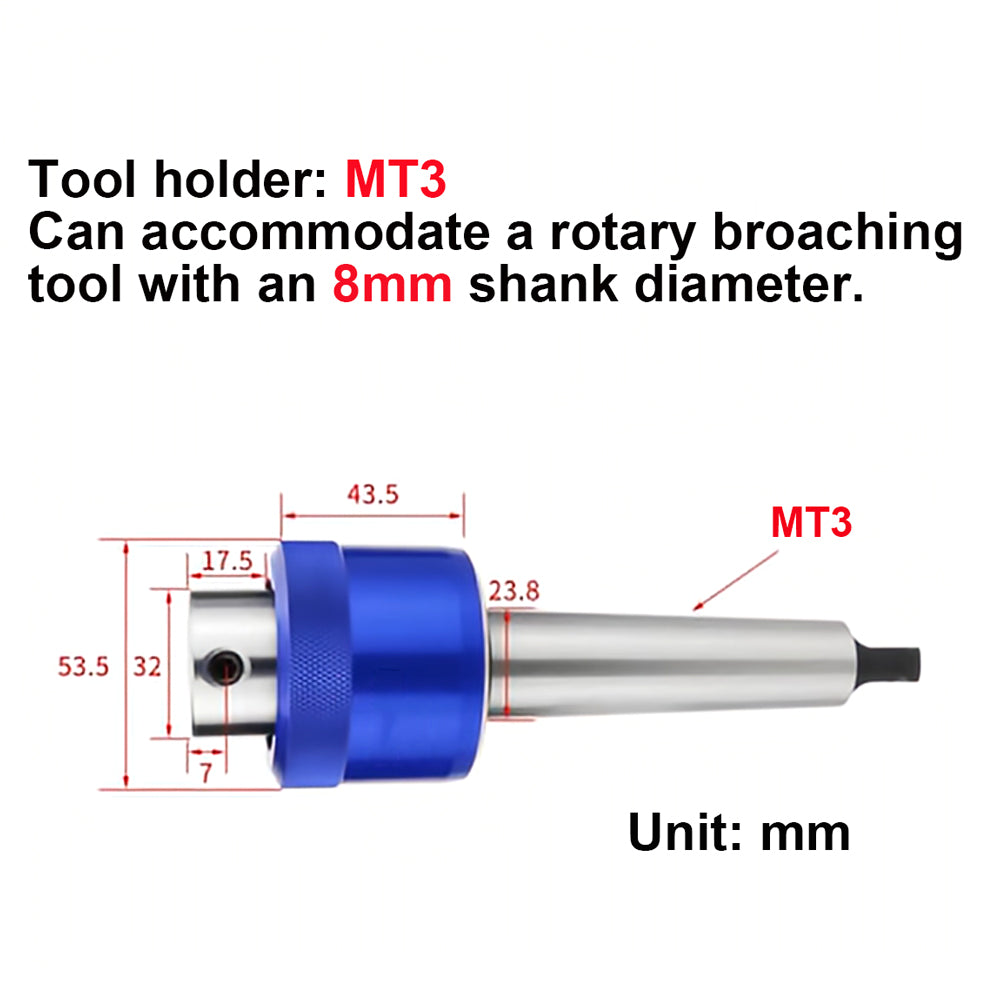

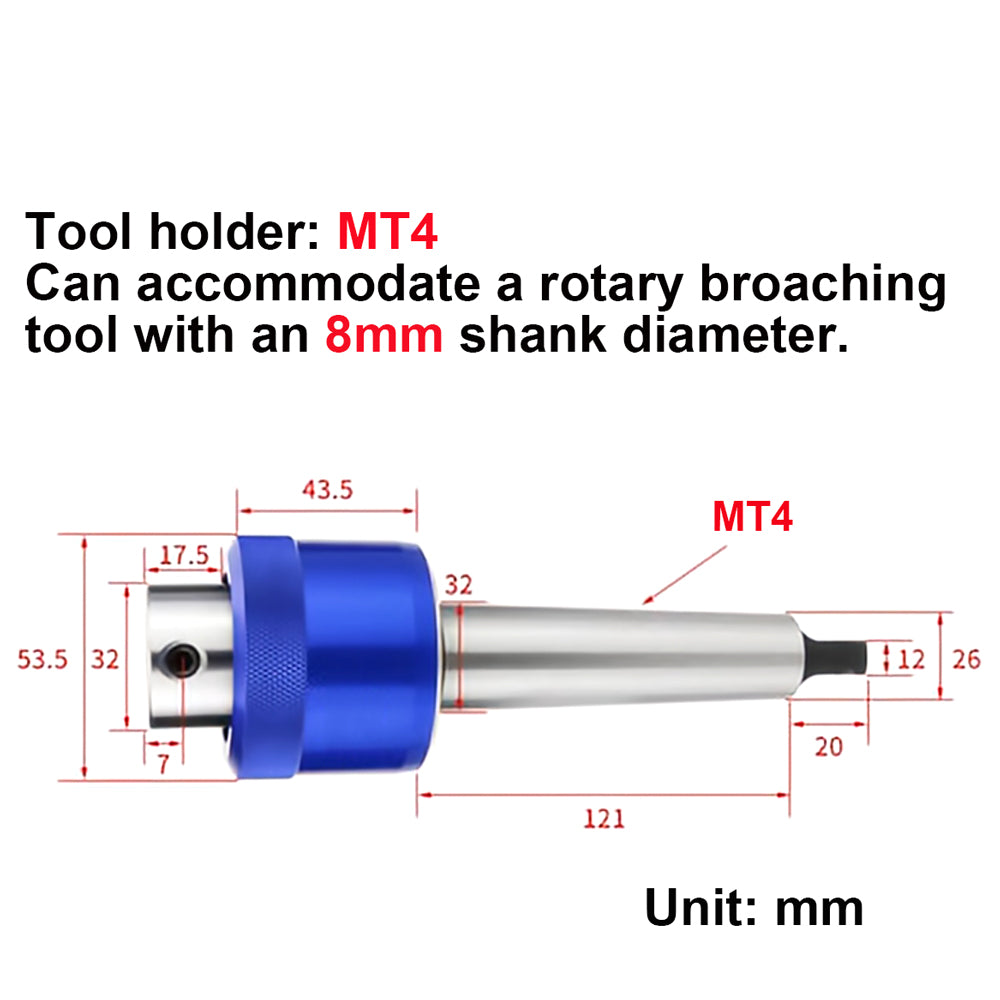

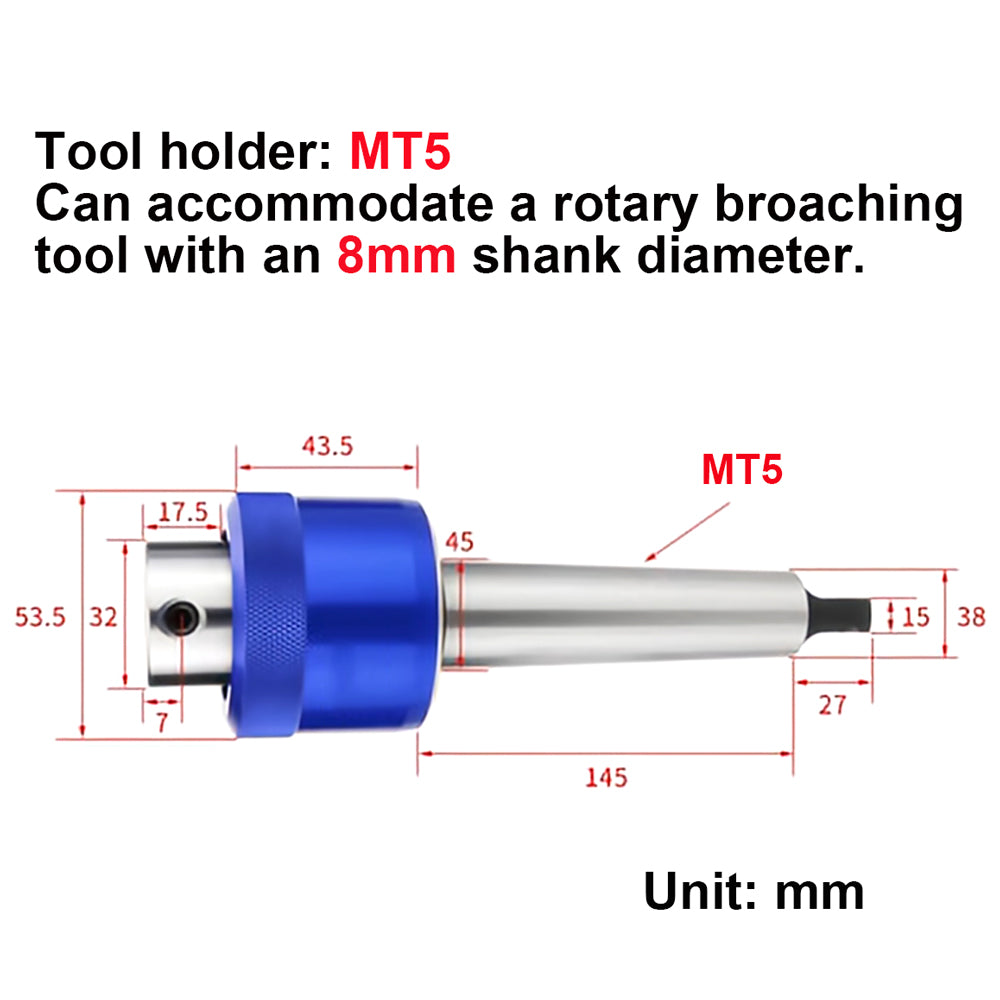

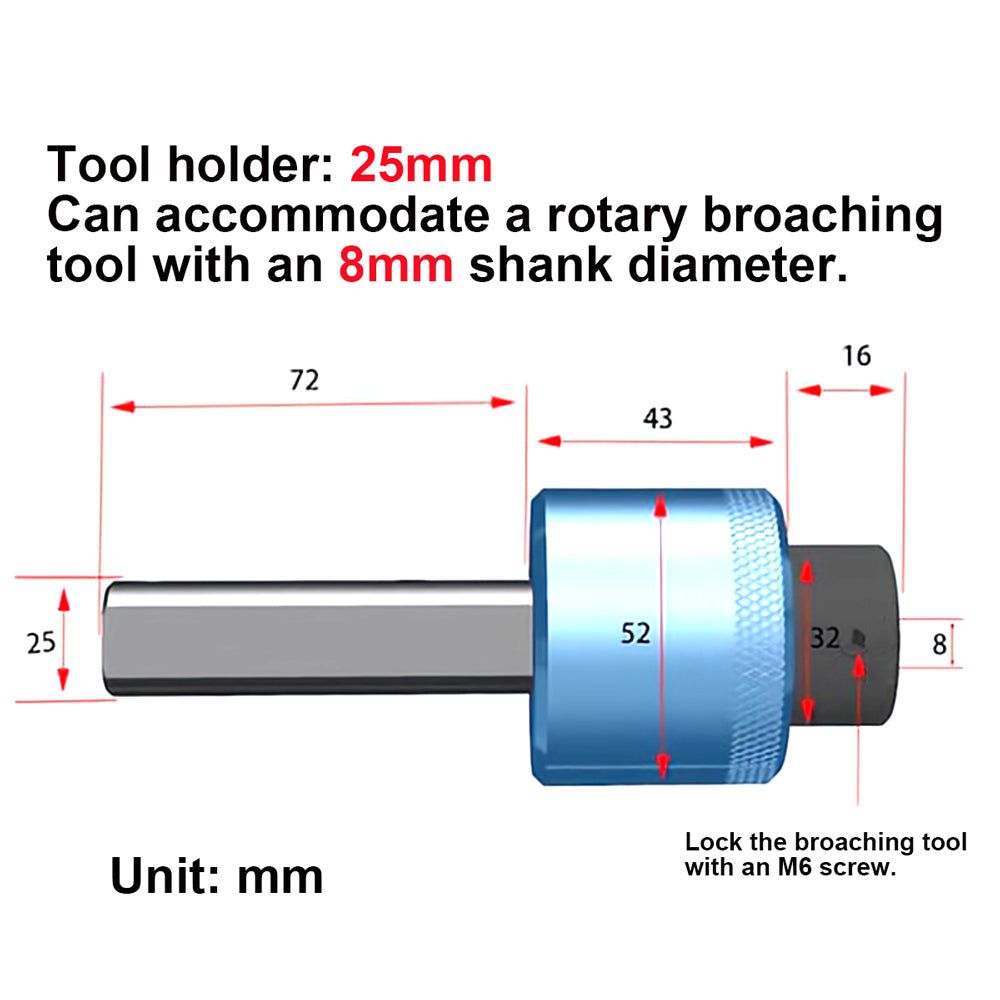

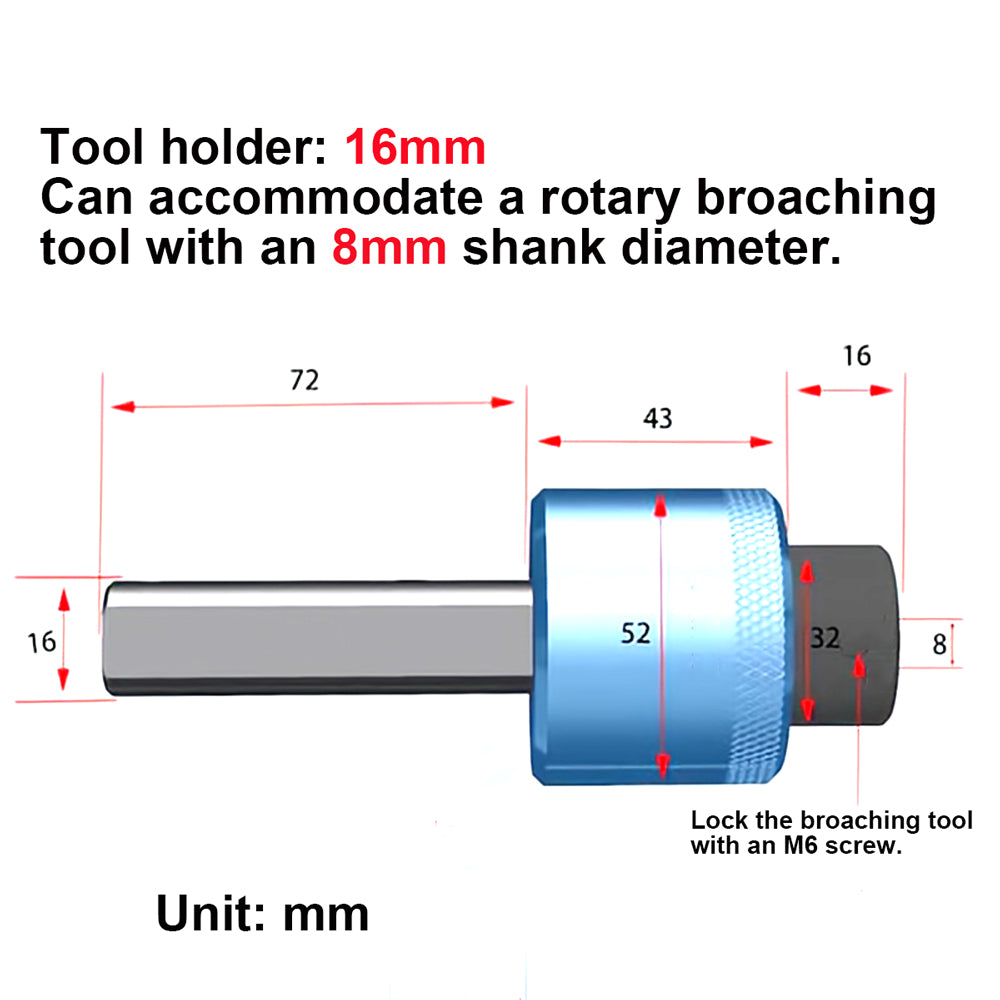

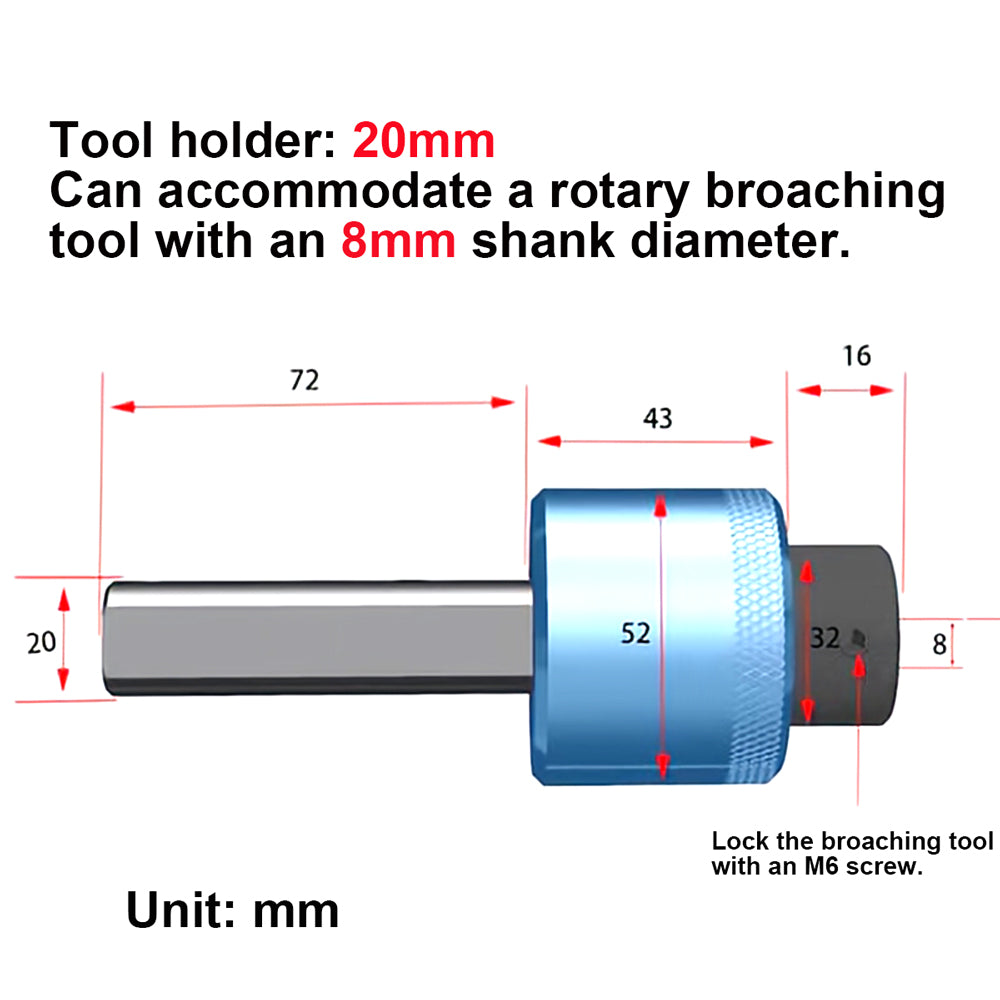

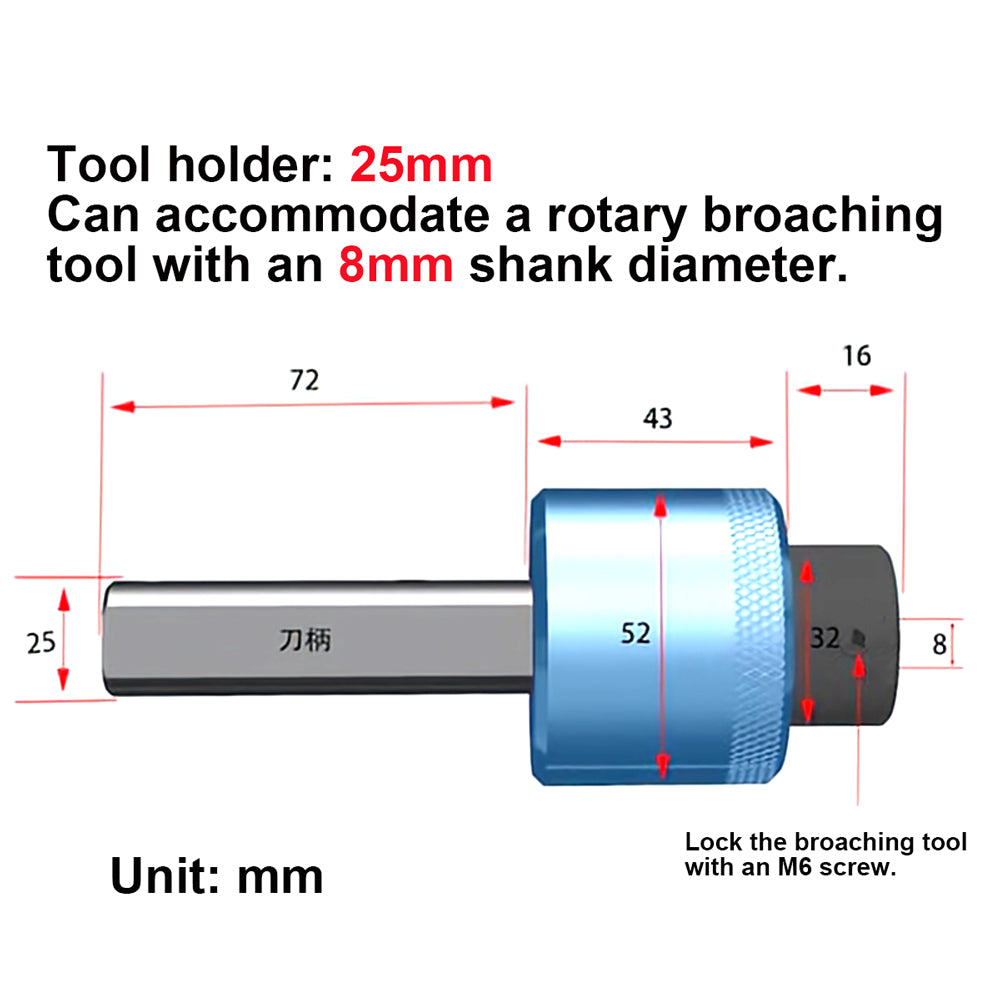

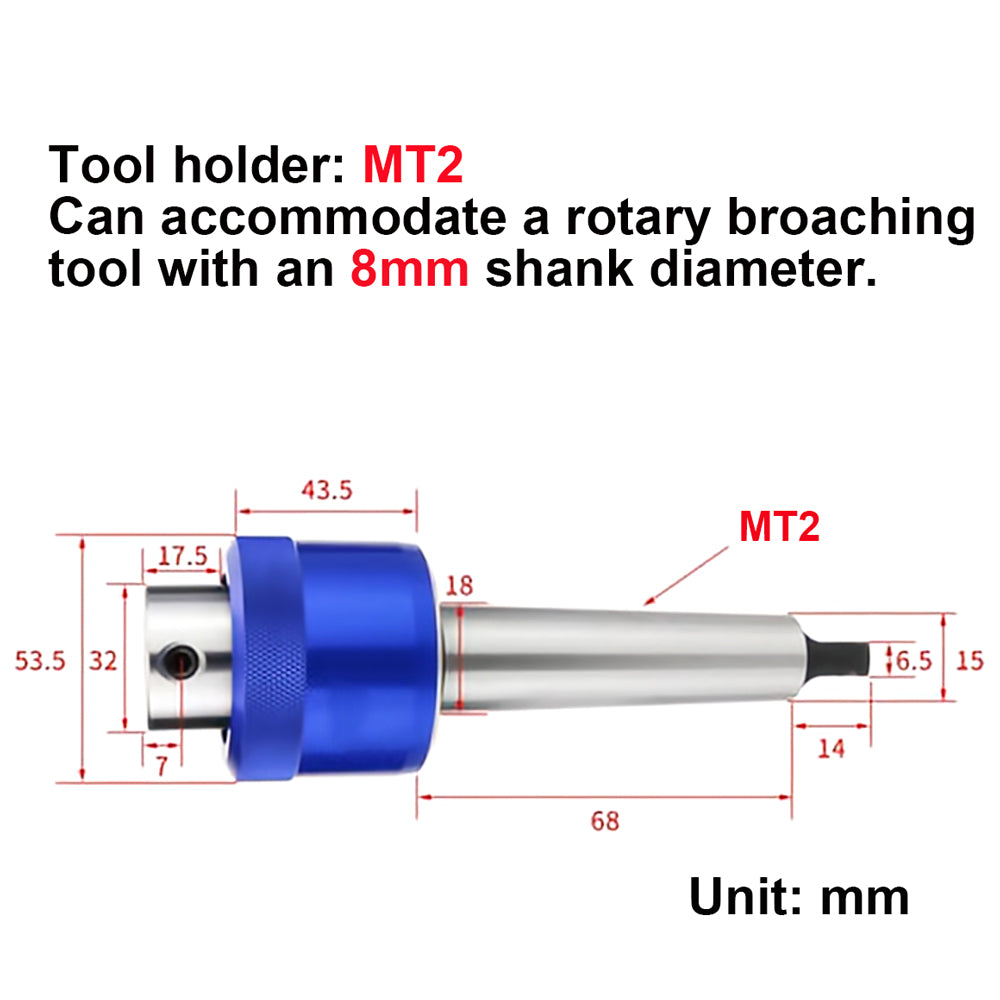

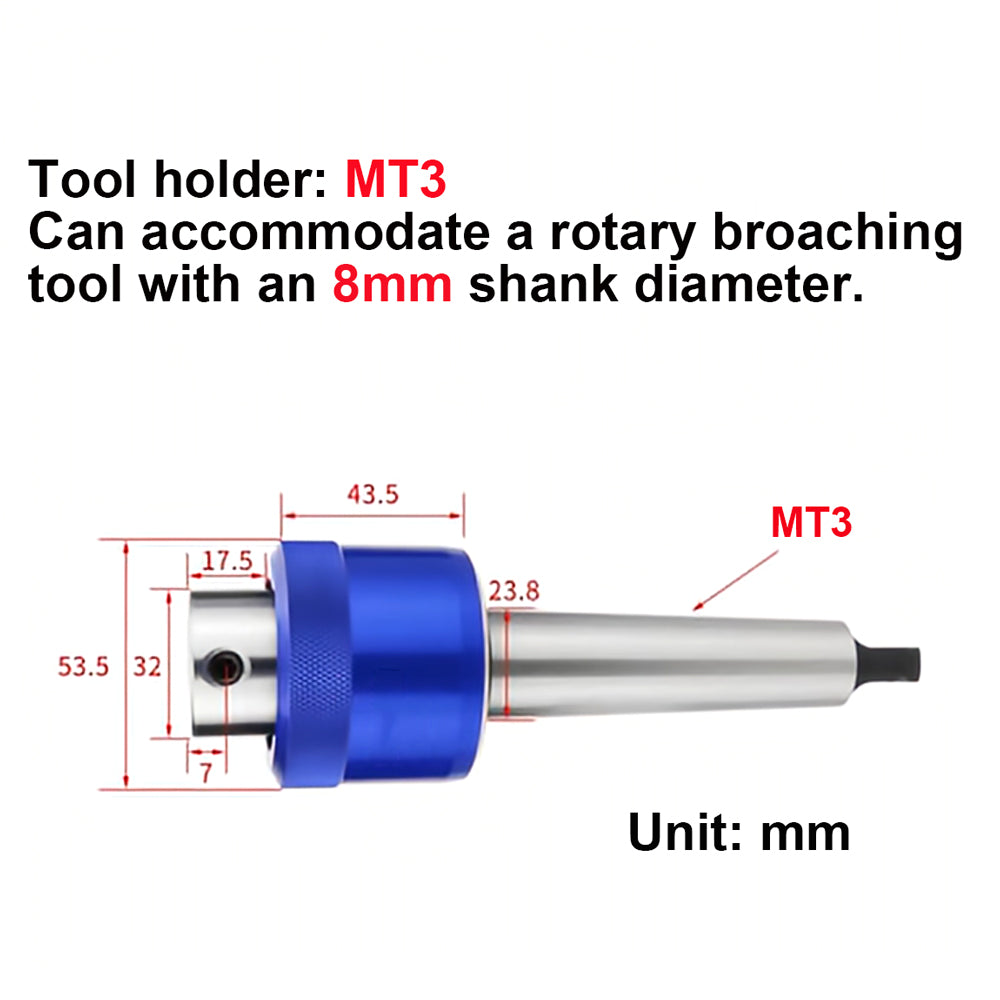

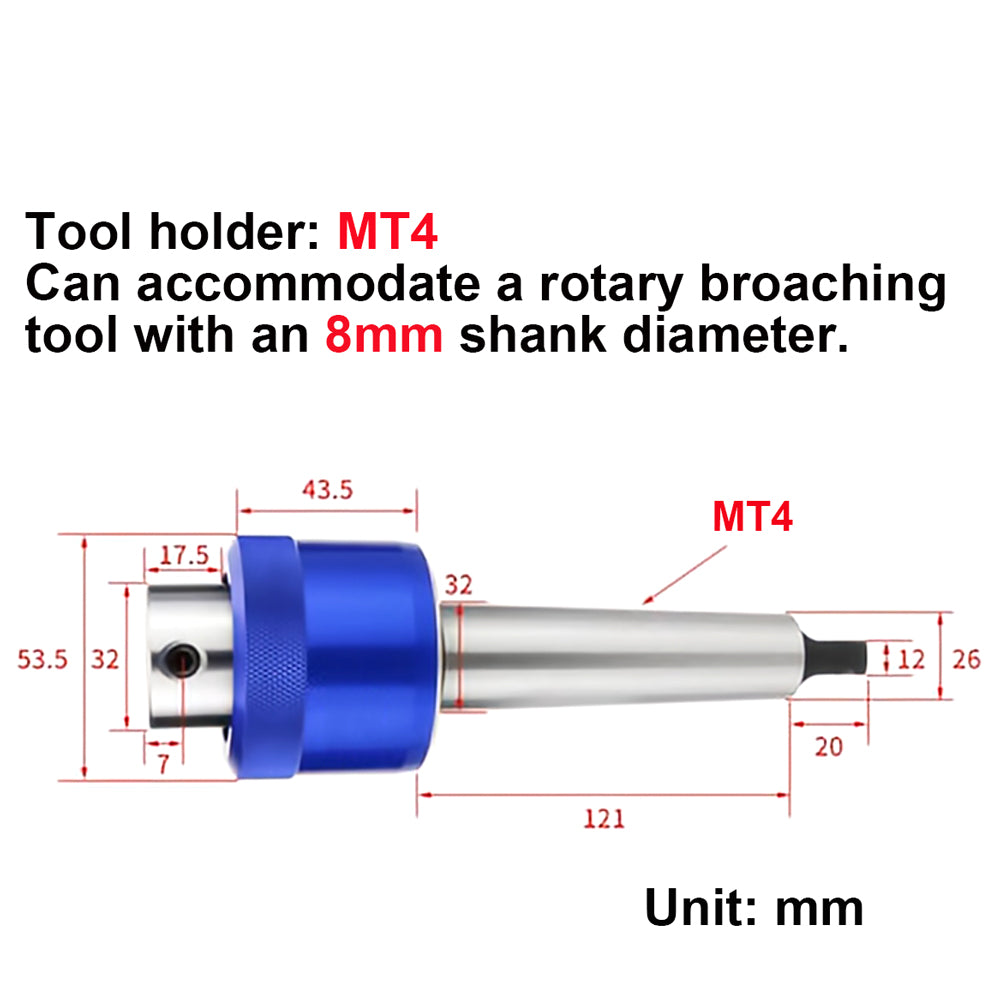

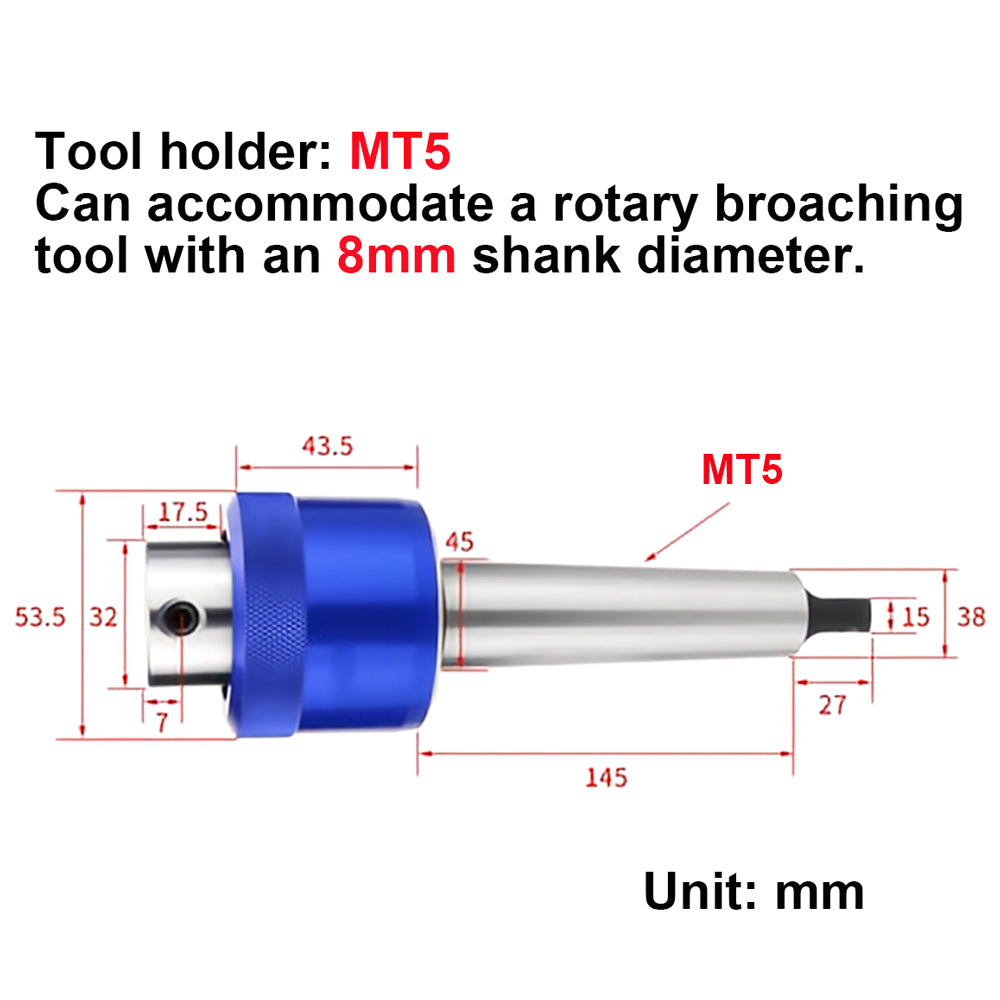

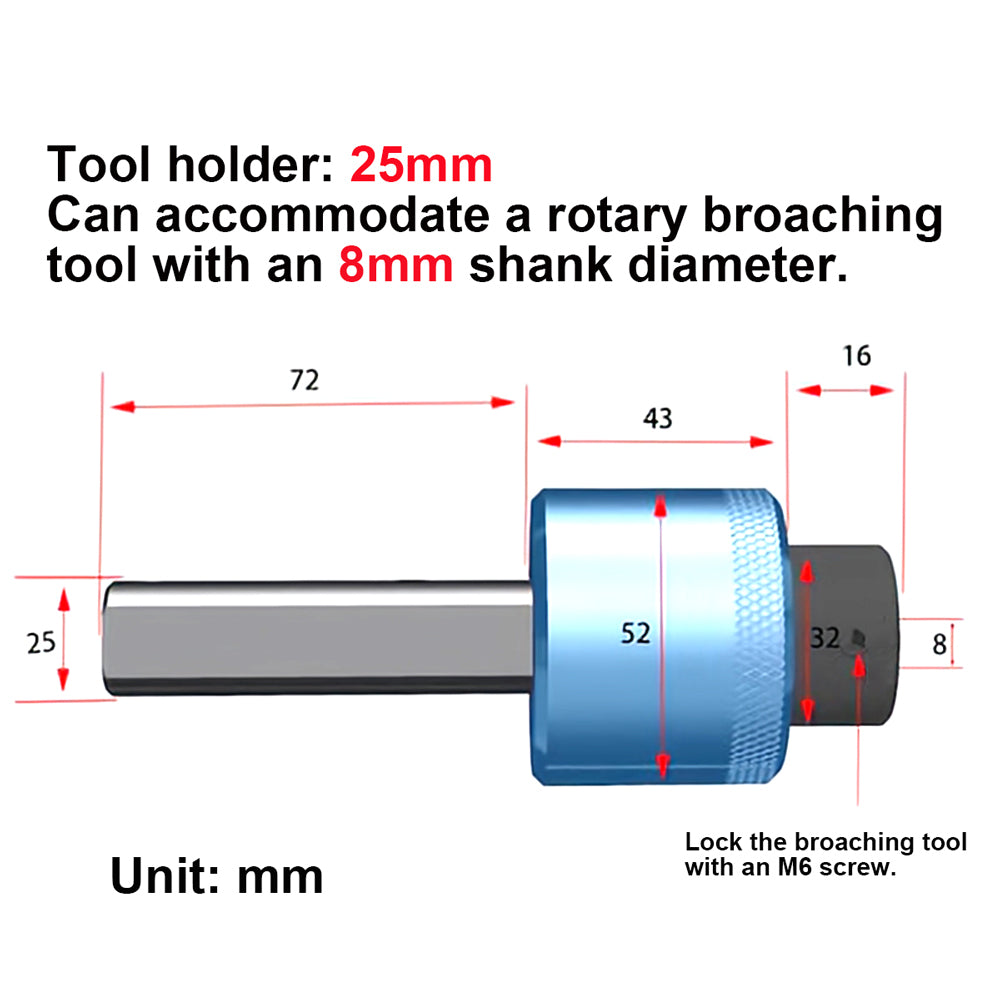

High precision:There are high precision bearings inside the tool handle, low rotation noise, high speed, not easy to heat. Tool handle grinding, with straight and taper handle can choose.

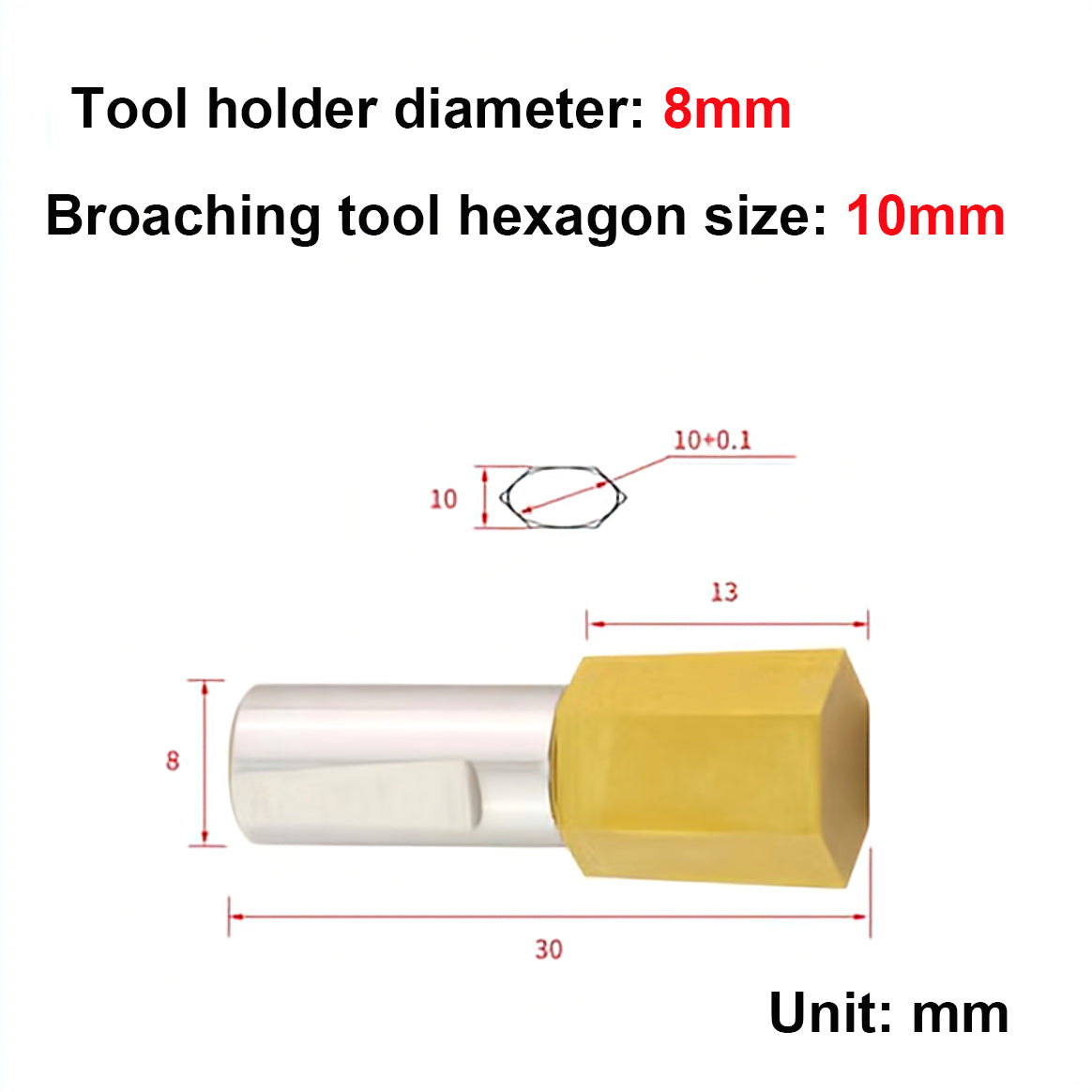

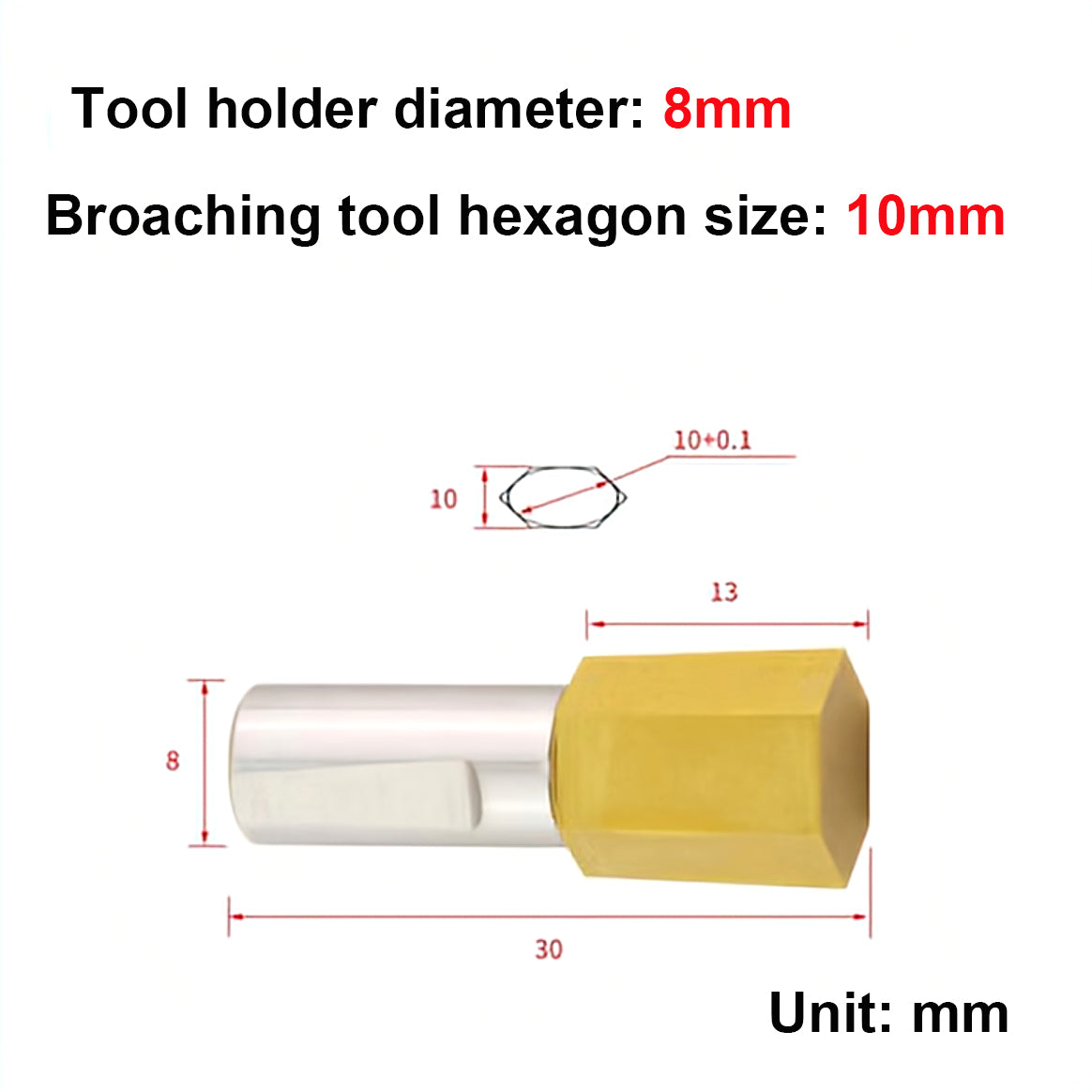

Parameters: Hexagon rotary broach shank diameter 8mm, Made of high wear-resistant alloy steel, surface coating treatment, hardness HRC60.

Simple clamping:The whole quenching treatment of the tool handle can quickly install the rotary broach, and lock it with screws to improve the clamping efficiency.

Processing parameters: The speed is recommended from 600 to 2000 rpm, steel is relatively slow 600-800 RPM, copper, aluminum can be used at high speed 800-2000 RPM. the feed rate is 0.02 to 0.1mm/rpm, if processing copper and aluminum materials, the processing of a hole takes only a few seconds.

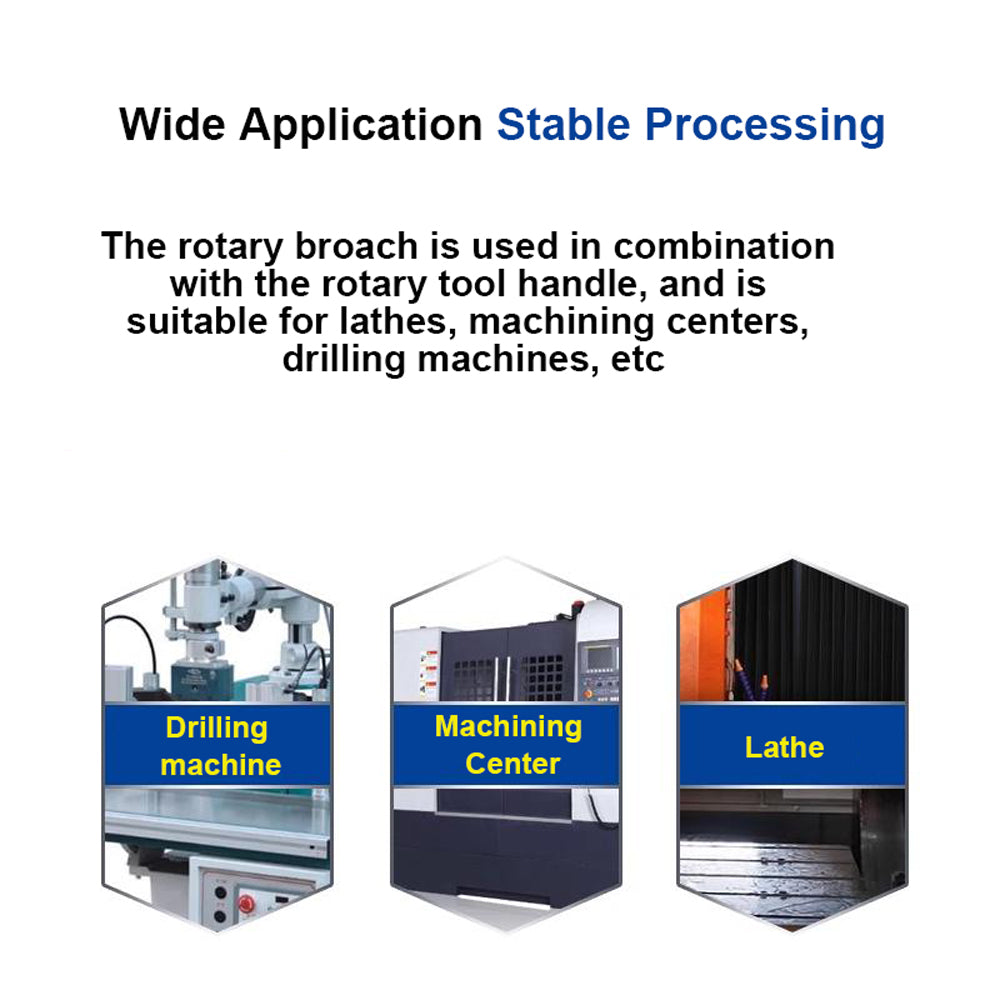

Wide applications: the punch needs to be matched with the tool handle, and can be used on lathes, drilling machines, milling machines, machining centers.

Disassembly

Loosen the locking screw with a wrench, fix the hexagonal part of the Rotary Broach in the vice clamp, and pull out the tail handle part to complete the disassembly.

Initial hole processing size before punching:

- Drilling diameter≥Blade to edge (tangent circle) dimensions

- The hole chamfer is 45 degrees, and the diameter of the chamfer hole is greater than the opposite corner of the blade, which has a guiding effect.

- Drilling depth ≥1.5 times the effective punching depth