RHKINGS

Universal Tungsten Steel Keyway Milling Cutter 2 Edge Carbide End Milling Cutter CNC Coating Tool

Universal Tungsten Steel Keyway Milling Cutter 2 Edge Carbide End Milling Cutter CNC Coating Tool

Couldn't load pickup availability

● 30-Day Money Back Guarantee

● We ship via FedEx/DHL/UPS. Delivery usually takes around 3 weeks from the date of your order.

● $4.99 for worldwide shipping or free shipping over $100

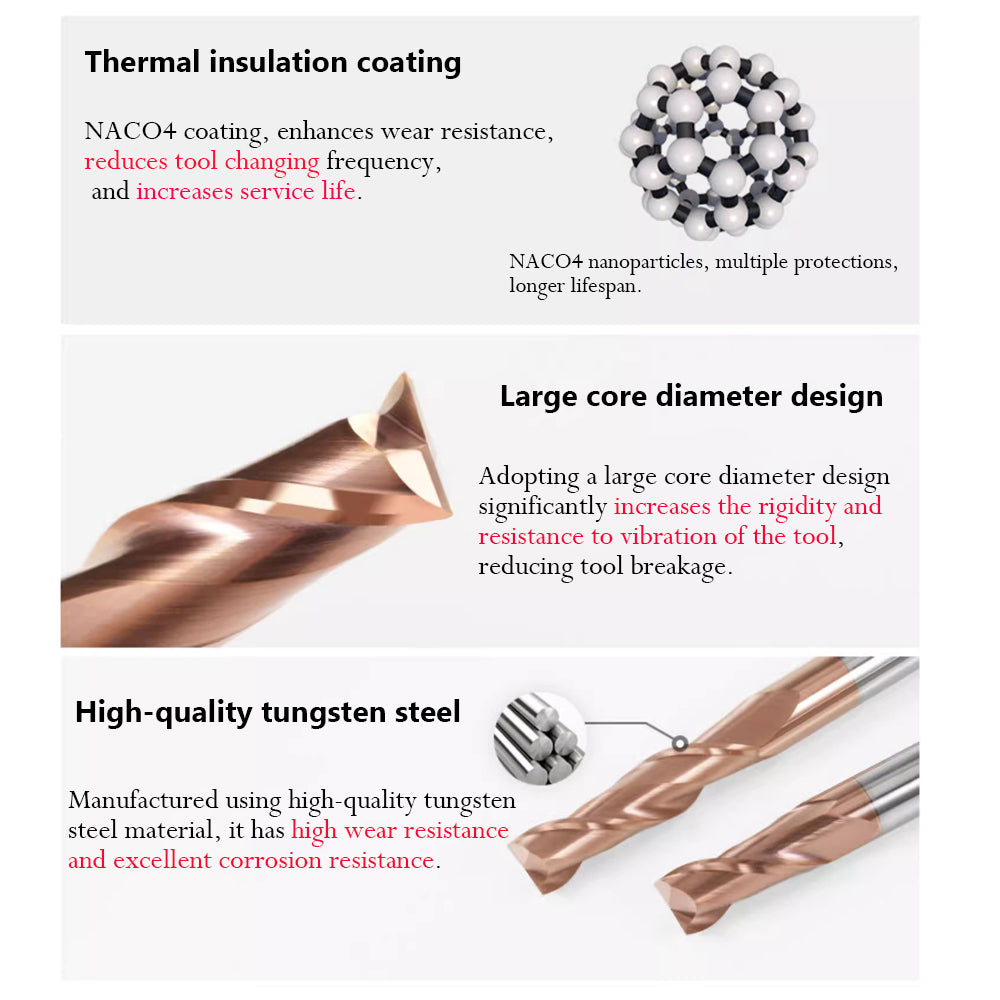

Advantages

1.The milling cutter is made of high-quality tungsten steel material, with high wear resistance and good corrosion resistance.

2.The keyway milling cutter has an NACO4 coating, which provides high temperature and wear resistance, reducing the need for tool changes and increasing its service life.

3.The surface of the milling cutter is passivated, ensuring corrosion resistance and preventing oxidation, thus ensuring the durability of the coating.

4.The design features a large core diameter, ensuring ample chip space. This design significantly enhances the tool's rigidity and anti-vibration performance, reducing the risk of milling cutter breakage.

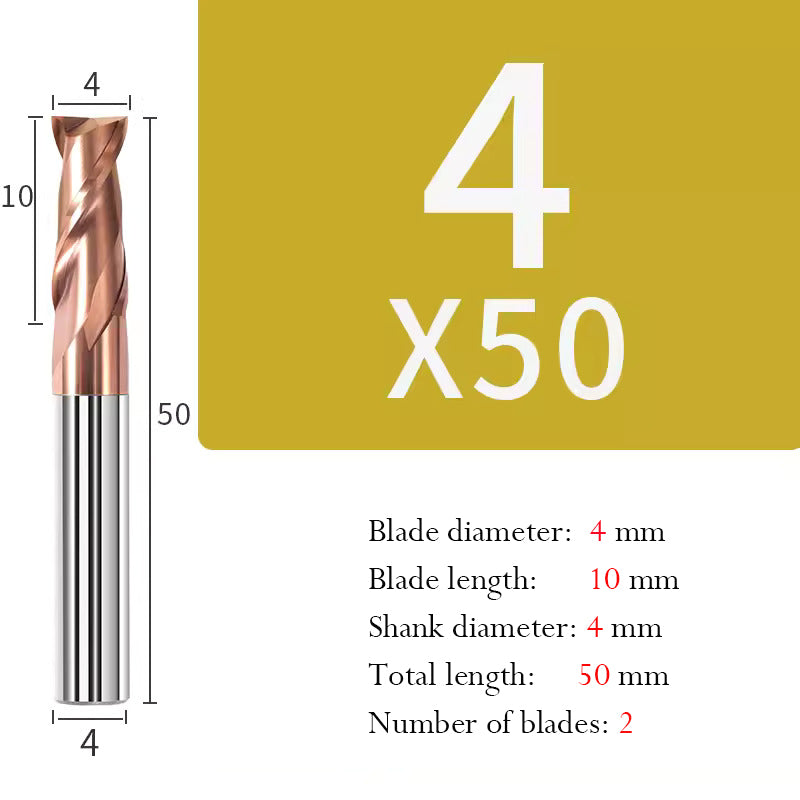

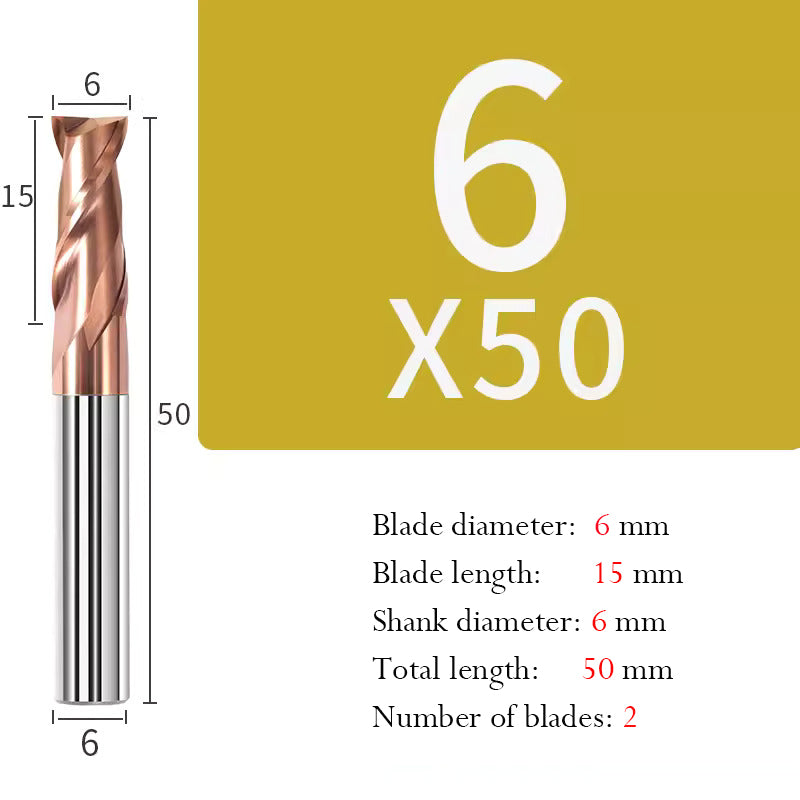

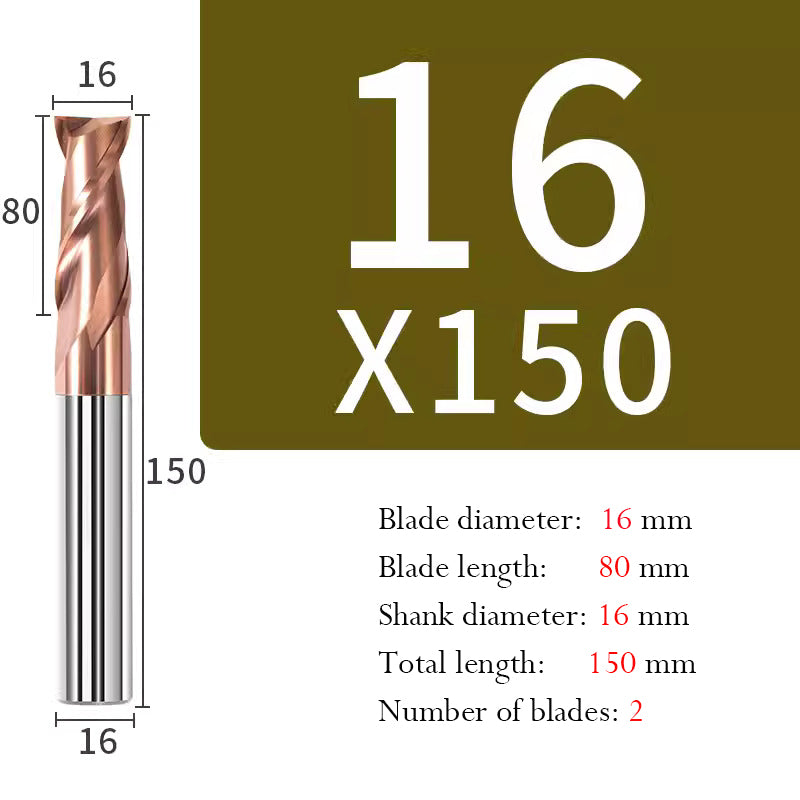

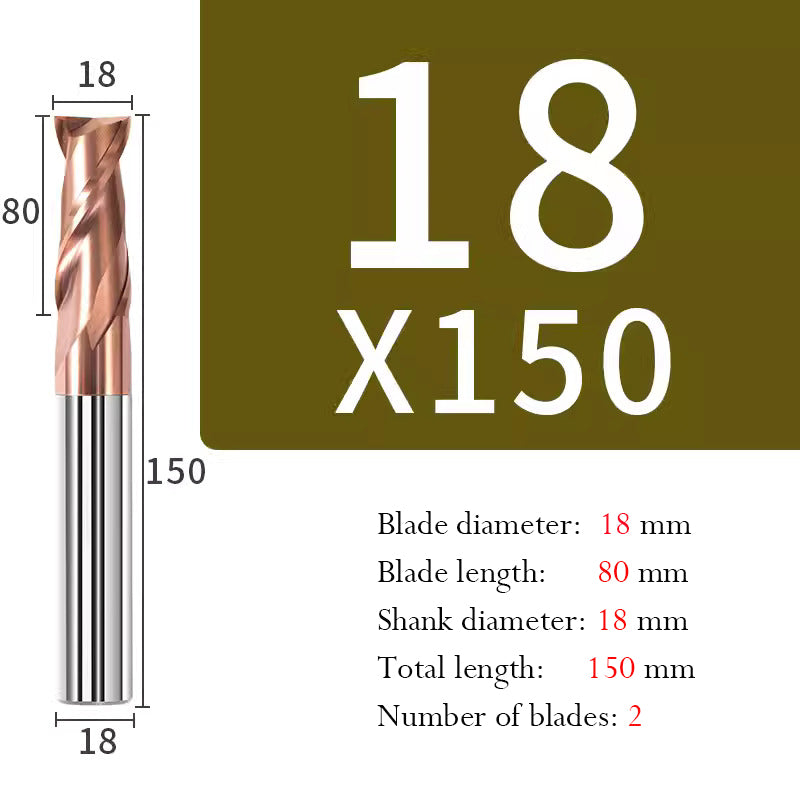

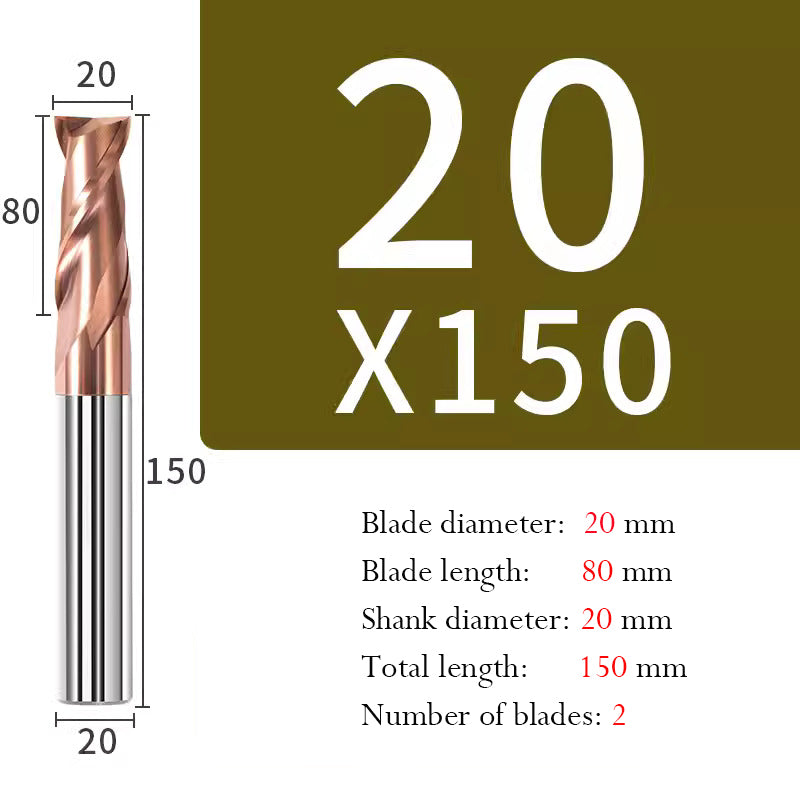

Parameters

Product Name: Keyway Milling Cutter

Material: Tungsten Steel Hard Alloy

Coating: NACO4 Nano Coating

Applicable Machining Range: Cast Iron, Carbon Steel, Stainless Steel, Alloy Steel

Machine Tool Compatibility: Suitable for CNC Machining Centers, CNC Milling Machines, Not suitable for low-speed machines such as bench drills and hand drills.

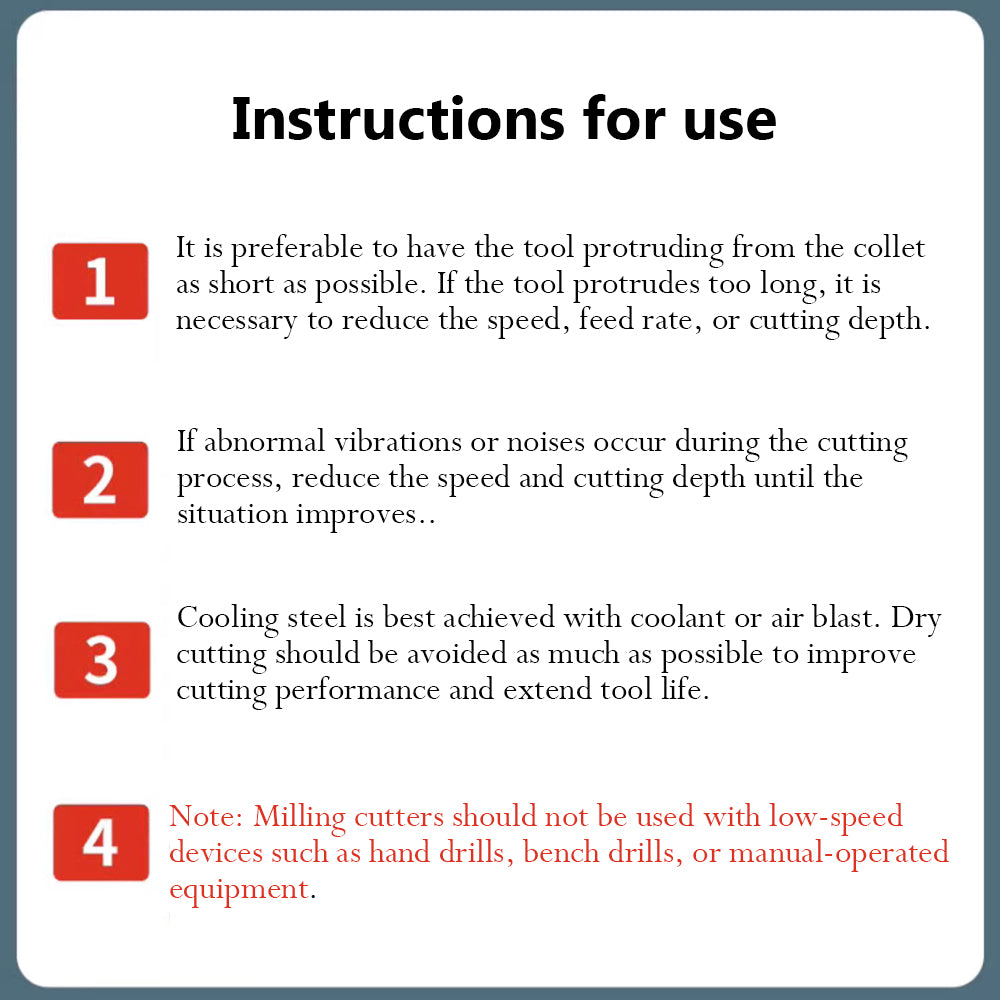

Instructions for use

1.It is preferable to have the tool protruding from the collet as short as possible. If the tool protrudes too long, it is necessary to reduce the speed, feed rate, or cutting depth.

2.If abnormal vibrations or noises occur during the cutting process, reduce the speed and cutting depth until the situation improves.

3.Cooling steel is best achieved with coolant or air blast. Dry cutting should be avoided as much as possible to improve cutting performance and extend tool life.

4.Note: Milling cutters should not be used with low-speed devices such as hand drills, bench drills, or manual-operated equipment.